Spiral Wound Gasket

※ Spiral Wound Gasket is the ideal gasket in the semi-metallic category. A narrow strip of V-shap metal hoop is spirally wound under tension with a filler cushion between the lamination of the metal and is spot-welded at both ends. This unique construction of a spring-like metal and soft filler provides gasket excel-lent characteristics:

※ Resistance to high temperature and high pressures.

※ Great resilience which allows the gasket to adjust automatically to change in operating conditions, such as pressure and thermal shocks, vibrations etc.

※ Excellent sealability is maintained with comparatively small gasket area.

※ Good tolerance for flange surface finish irregularities.

※ Can be designed to any dimensions economically in circular or moderately noncircular shape. Available in a variety of hoop metals and filler materials to satisfy specific operating conditions.

※

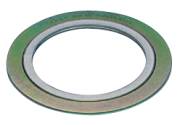

Material & Structure:

|

Type |

Cross section |

Hoop material |

Filler material |

Inner, Outer ring ma |

Normal Thickness |

|

Basic type |

|

SUS304,316,321Ti,Monel etc. As specified Stainless steel tape. |

Asbestos |

Carbon steel sheetor SUS304,306 etc. As specified sheet |

V-shaped |

W-shaped |

|

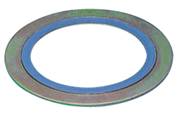

With inner ring |

|

Non-asbestos |

3.2

4.5 |

2.5

4.8

5.5

7.5 |

|

With outer ring |

|

Expanded graphite |

|

With inner & out ring |

|

PTFE |

※

Gross section and Number:

|

Type |

Hoop material |

Asbestos |

Non-asbestos |

Graphite |

PTFE |

|

Basic type |

SUS304 |

104 |

204 |

304 |

404 |

|

SUS316 |

106 |

206 |

306 |

406 |

|

As specified |

109 |

209 |

309 |

409 |

|

With inner ring |

SUS304 |

114 |

214 |

314 |

414 |

|

SUS316 |

116 |

216 |

316 |

416 |

|

As specified |

119 |

219 |

319 |

419 |

|

With outer ring |

SUS304 |

124 |

224 |

324 |

424 |

|

SUS316 |

126 |

226 |

326 |

426 |

|

As specified |

129 |

229 |

329 |

429 |

|

With inner & out ring |

SUS304 |

134 |

234 |

334 |

434 |

|

SUS316 |

136 |

236 |

336 |

436 |

|

As specified |

139 |

239 |

339 |

439 |

(1) Asbestos Spiral Would Gasket:

※ This spiral wound gasket uses asbestos paper as the filler. It is the most popular type in a wide range of fields.

※

Feature:

The most economical gasket among varies types of other Spiral Wound Gaskets.

※

Applications:

Suitable for use in piping flanges, pressure vessels, heat exchangers, valve bonnets, etc. in a variety of industries.

※

Service Range:

|

Fluid |

Maximum service temperature °C |

Maximum service pressure |

|

Water type fluids |

600 |

Class 2500 |

|

Oil type fluids |

500 |

Class 1500 |

|

Gas type fluids |

400 |

Class 600 |

(2) Na Spiral Would Gasket

※ Instead of conventional asbestos filler, this type uses inorganic fibers and aramid fibres as a nonasbestos paper filler.

※

Feature:

1. Asbestos fibers are used.

2. The service range(heat resistance, pressure resistance) is different from that of the asbestos SWG, but the sealing performance is almost the same.

※

Applications:

Suitable for use in piping flanges, pressure vessels, heat exchangers, valve bonnets, etc., in a variety of industries, especially in locations where asbestos is not allowed.

※

Service Range:

|

Fluid |

Maximum service temperature °C |

Maximum service pressure |

|

Water type fluids |

350 |

Class 1500 |

|

Oil type fluids |

350 |

Class 600 |

|

Gas type fluids |

350 |

Class 400 |

(3)PTFE Spiral Would Gasket

※

The gasket uses unsintered PTFE tapes as the filler material. The PTFE filler provides superior chemical resistance and sealabining with strongly corrosion resistant metals, it can be applied for corrosive fluids, pure oxygen gas and vacuum lines.

※

Feature:

1. Sealability is superior to that of other SWG gasket. Usage is possible even with vacuum lines.

2. Excellent corrosion resistance makes it suitable for almost all types of fuild by selecting appropriate hoop materials.

3. Not used for glass or rubber lined flange, glass or porcelain flange.

※

Service Range:

|

Fluid |

Maximum service temperature °C |

Maximum service pressure |

|

Water type fluids |

300 |

Class 600 |

|

Oil type fluids |

300 |

Class 600 |

|

Gas type fluids |

300 |

Class 600 |

(4) Graphite Spiral Would Gasket

※ The gasket uses expanded graphite tape as the filler material which provides superb sealability even under severe conditions such us high temperature, high pressure, cryogenic temperatures, heat cycles, temperature cycles and so on.

※

Feature:

1. Sealing, especially gas sealing, is superior to that of asbestos gaskets.

2. Little deterioration of the filler material at high temperatures, outstanding long-term sealability even under high temperatures and high pressures.

3. Sealing remains outstanding even under servere conditions such as pressure fluctuations and heat cycles.

4. Excellent sealability is maintained making it possible to apply this for corrosive fluids by selecting the appropriate materials.

5. Outstanding sealing even at cryogenic temperatures.

※

Service Range:

|

Fluid |

Maximum service temperature °C |

Maximum service pressure |

|

Water type fluids |

450(650) |

Class 2500 |

|

Oil type fluids |

450(800) |

Class 1500 |

|

Gas type fluids |

450(800) |

Class 1500 |

|

Cryogenic temperature fluid |

-240 |

20 MPa |

※

Notes: The values in brackets () are maximum service temperature under a non-oxidizing atmosphere. When using with RF flanges in open air, the Max. service temperature is 450°C.

(5) Non-Circular Spiral Would Gasket:

※ Spiral Wound M series are designed and manufactured for boiler manholes and handholes, valve bonnet covers etc. In required shapes and dimensions for service pressure range from 550LB to 2500LB. 5504-M is manufactured with SUS 304 and asbestos paper filler, and 5506-M with SUS316. 5509-M is manufactured with other metals on request.

※ Other asbestos free types are also available on request.

※ Service Temperature: 5504-M: up to 500°C

5506-M: up to 580°C

Obround Oval Diamond Square or rectangul

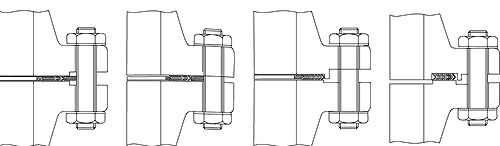

※ Flange types and suitable gasket types

|

Full face (FF) |

Raised face (RF) |

Male & Female (M & F) |

Tongue & Groove (T & G) |

|

|

|

with inner and outer ring |

with inner and outer ring |

with inner ring |

Basic type |

※

The type without an inner ring can be used if the following conditions are fully satisfied.

※

Filler material: NA or asbestos.

※ Pressure rating: Class 600 or below, or 40K or below.

※ Size: Nominal diameter 24B or below, or 600A or below. |